The U.S. Aerospace and Defense Materials Market is projected to grow from USD 7.69 billion in 2025 to USD 11.41 billion by 2035, supported by defense modernization programs, aerospace manufacturing strength, and continued investment in advanced material technologies.

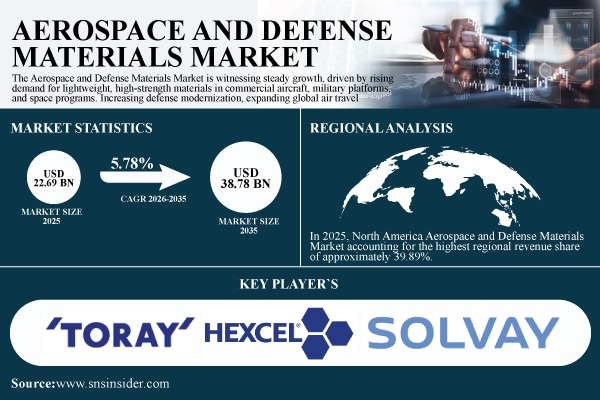

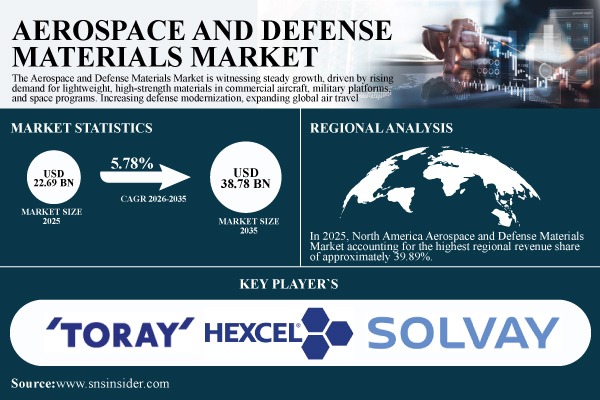

Austin, Feb. 10, 2026 (GLOBE NEWSWIRE) — The Aerospace and Defense Materials Market was valued at USD 22.69 Billion in 2025 and is expected to reach USD 38.78 Billion by 2035, growing at a CAGR 5.78% over the forecast period.

The market for aerospace and defense materials is expanding steadily due to the growing need for strong, lightweight materials for space programs, military platforms, and commercial aircraft.

Download PDF Sample of Aerospace and Defense Materials Market @ https://www.snsinsider.com/sample-request/9545

The U.S. Aerospace and Defense Materials Market is projected to grow from USD 7.69 Billion in 2025 to USD 11.41 Billion by 2035, at a CAGR of 3.11%.

Continued defense modernization, more spending on cutting-edge aircraft and space programs, and the gradual replacement of older fleets are the main factors propelling the growth of the U.S. Aerospace and Defense Materials Market.

Rising Demand for Lightweight and High-Strength Materials to Drive Market Growth Globally

Lightweight, high-strength materials including titanium, aluminum alloys, and innovative composites are in high demand because to the growing need to enhance operational performance, cargo capacity, and fuel efficiency in commercial and military aircraft. In order to satisfy strict performance and emission requirements, aircraft manufacturers are increasingly substituting composite airframes and next-generation alloys for conventional steel components. These materials are essential for next-generation aerospace platforms as they allow for lighter aircraft, greater durability, and higher resistance to corrosion.

Segmentation Analysis:

By Material Type

Aluminum alloys dominate the material type segment due to their widespread use in airframes, fuselage structures, wings, and structural components across commercial and military aircraft. Composites represent the fastest-growing segment, driven by the aerospace industry’s shift toward lightweight materials to improve fuel efficiency and reduce emissions.

By Manufacturing Technology

Advanced machining and forging dominate the manufacturing technology segment due to their established role in producing high-strength, safety-critical aerospace components. Additive manufacturing is the fastest-growing technology segment, driven by its ability to produce complex geometries, reduce material waste, and shorten production lead times.

By Application

Airframe and structural components lead the application segment due to high material consumption in fuselage sections, wings, frames, and load-bearing structures. Engine and propulsion systems are the fastest-growing application segment, supported by increasing demand for high-temperature-resistant materials such as titanium alloys, superalloys, and ceramic matrix composites.

By End-User

Commercial aviation dominates the end-user segment due to sustained aircraft deliveries, fleet modernization programs, and rising global air passenger traffic. Space and satellite systems represent the fastest-growing end-user segment, driven by increasing satellite launches, space exploration missions, and commercial spaceflight initiatives.

If You Need Any Customization on Aerospace and Defense Materials Market Report, Inquire Now @ https://www.snsinsider.com/enquiry/9545

Regional Insights:

In 2025, North America aerospace and defense materials market accounting for the highest regional revenue share of approximately 39.89%. This dominance is driven by North America’s strong aerospace manufacturing base, high defense spending, and the presence of major aircraft OEMs and material suppliers.

The fastest-growing region is Asia Pacific, which is predicted to expand at a CAGR of 8.87% between 2026 and 2035. Large-scale domestic aircraft and defense production projects in China, India, Japan, and South Korea, as well as growing commercial aviation fleets and defense expenditures, are the main drivers of this quick expansion.

Key Players:

- Toray Industries, Inc.

- Hexcel Corporation

- Solvay S.A.

- Constellium SE

- Allegheny Technologies Incorporated (ATI)

- Carpenter Technology Corporation

- Teijin Limited

- Materion Corporation

- Arconic Corporation

- Howmet Aerospace Inc.

- Alcoa Corporation

- Novelis Inc.

- VSMPO-AVISMA Corporation

- Kobe Steel Ltd.

- AMG Advanced Metallurgical Group N.V.

- SGL Carbon SE

- Huntsman International LLC

- 3M Company

- Rogers Corporation

- SABIC (Saudi Basic Industries Corporation)

Recent Developments:

June 2025, Toray expanded its aerospace-grade carbon fiber and composite prepreg production capacity to support next-generation commercial aircraft and defense programs, focusing on lightweight and low-emission aviation platforms.

May 2025, Hexcel announced new investments in high-performance composite materials and automation technologies to enhance production efficiency and meet growing demand from defense aircraft, space launch systems, and next-generation air mobility platforms.

Buy Full Research Report on Aerospace and Defense Materials Market 2026-2035 @ https://www.snsinsider.com/checkout/9545

Exclusive Sections of the Report (The USPs):

- ADOPTION TRENDS OF LIGHTWEIGHT AND HIGH-STRENGTH MATERIALS – helps you understand the shift toward advanced materials aimed at weight reduction, fuel efficiency, and enhanced structural performance across aerospace and defense platforms.

- METAL VS COMPOSITE MATERIAL USAGE RATIO – helps you evaluate the balance between traditional metallic materials and advanced composites across commercial, military, and space aerospace applications.

- STRUCTURAL VS NON-STRUCTURAL MATERIAL CONSUMPTION – helps you identify how material demand is distributed between load-bearing structures and non-structural components such as interiors and secondary assemblies.

- PLATFORM-WISE MATERIAL UTILIZATION PATTERNS – helps you assess differences in material adoption across aircraft types, including fixed-wing, rotary-wing, unmanned aerial vehicles, and space systems.

- MATERIAL SUBSTITUTION AND OPTIMIZATION TRENDS – helps you track replacement of conventional materials with advanced alternatives to improve durability, performance, and lifecycle efficiency.

About Us:

SNS Insider is one of the leading market research and consulting agencies that dominates the market research industry globally. Our company’s aim is to give clients the knowledge they require in order to function in changing circumstances. In order to give you current, accurate market data, consumer insights, and opinions so that you can make decisions with confidence, we employ a variety of techniques, including surveys, video talks, and focus groups around the world.

CONTACT: Rohan Jadhav - Principal Consultant Phone: +1-315 636 4242 (US) | +44- 20 3290 5010 (UK)

Disclaimer: The above press release comes to you under an arrangement with GlobeNewswire. IndiaShorts takes no editorial responsibility for the same.